Circular economy

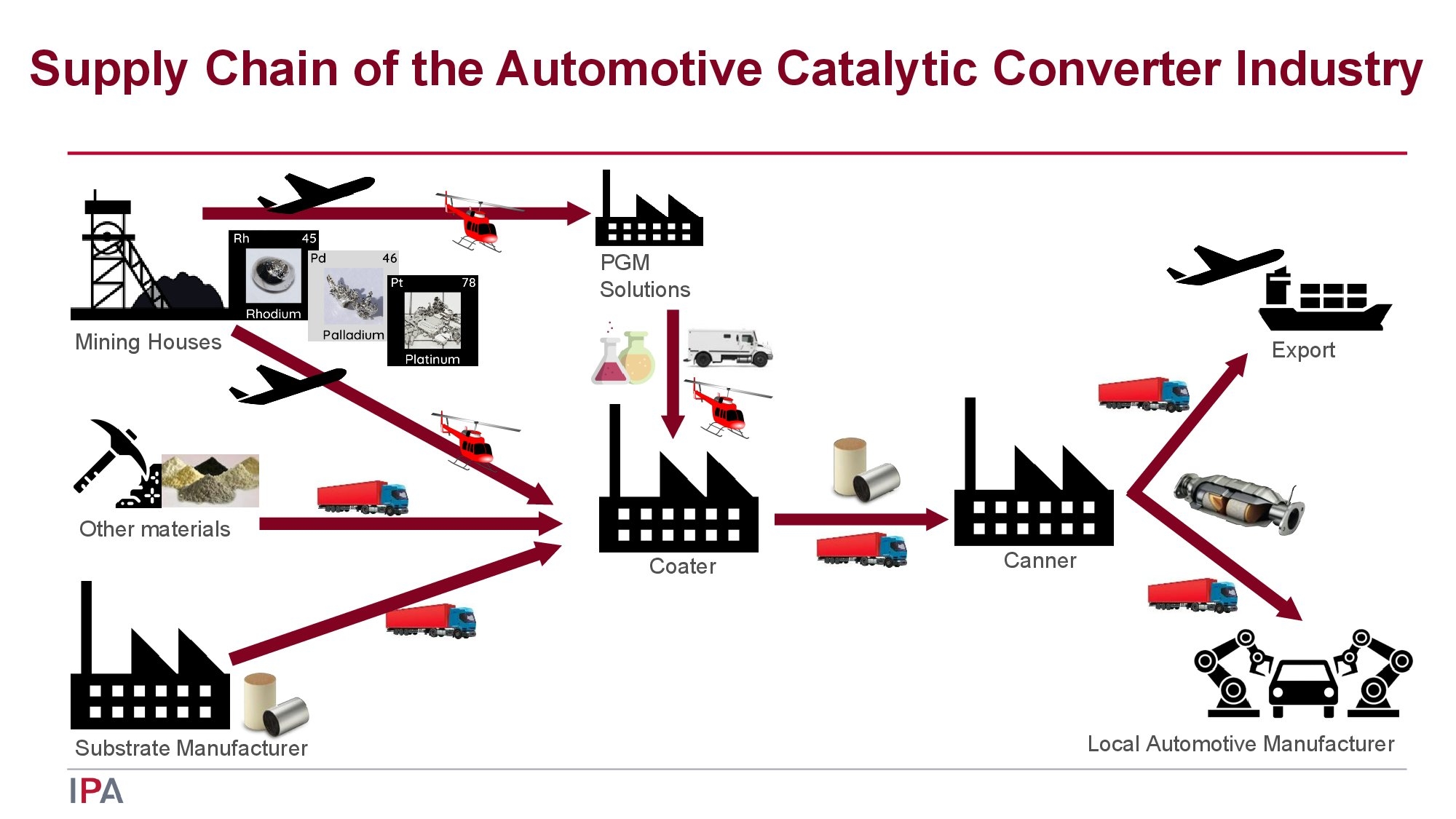

Platinum group metals (PGMs) move across borders in a wide range of different parts and products and the metals may not appear explicitly in trade data. For example, automotive emissions control catalysts containing PGMs may be produced in one region, shipped to another region for canning, then move forward to another for fitment onto new vehicles, and then these vehicles can be exported to yet another region for sale; none of this will be captured as an obvious PGM movement in trade data.

Toll refining

It is normal within the PGM industry for the physical location of metal to be a different region or country from where the owner is located, greatly complicating any determination of domestic ‘self-sufficiency’ in PGMs. The refiners and fabricators frequently process metal on behalf of their customers and do not own the metal themselves during this process. This also means that imports are not always undertaken by the owner of the metal – particularly for recycling, which is often performed as a service by the secondary refiner on behalf of the metal owner (referred to as toll refining).

Circularity is already established in the PGM industry

The metals are routinely recycled today, and recycled PGMs and virgin PGMs are completely fungible: this is crucial to ensure the sustainable use of PGMs. The existing global PGM recycling infrastructure must be exploited to support the hydrogen economy as fuel cells and electrolysers scale up. Technical recyclability of PGMs is very high, so any significant metal losses usually occur due to inefficient collection.

Effective strategies for end-of-life management of equipment containing PGMs must be established to minimise collection losses and ensure every gram of PGMs can be reused. There is also scope for improved collection of the metals from existing applications to boost the recycled supply of these metals. Policies improving the collection of end-of-life PGM-containing equipment are essential to help to maximise recycling.