PGMs in the workplace

The main health effect of concern associated with PGMs is the potential for some forms of platinum to cause respiratory sensitisation (allergy) – commonly called Platinum Salt Sensitivity (PSS).

PSS has almost exclusively been confined to workers exposed to certain compounds of platinum known as complex halogenated platinum salts (CHPS), of which chloroplatinates are the most common forms.

The IPA Health and Environment Science Committee has been actively engaged in driving forward the understanding of PSS for a number of years. During this time, various research and other programmes have been successfully delivered addressing key areas including:

- improved understanding of the exposure-response relationship for occupational PSS through the sponsorship of an epidemiology study;

- development and implementation of an improved method for industrial hygiene sampling and analysis of airborne platinum; and

- the collation and dissemination of state-of-the-science information about working safely with PGMs within an IPA Guidance Document.

Further information on these and other topic can be found below.

Workplace Guidance Document - Safe Use of PGMs in the Workplace

The Guide "Safe Use of Platinum Group Metals in the Workplace" is a 2017 sector-wide consensus document promoting the safe handling of PGMs in the workplace. It is targeted at health professionals and those responsible for day-to-day operations in the industry. It is a valuable guide in advancing awareness of the hazards and risks associated with occupational exposure to PGMs, and how to effectively manage them.

The main health effect of concern for certain forms of platinum in industrial settings is respiratory sensitisation, commonly referred to as platinum salt sensitivity (PSS). It has almost exclusively been confined to workers exposed to certain compounds of platinum known as complex halogenated platinum salts (CHPS), of which chloroplatinates are the most common forms.

NOTE: This Guide was prepared by independent consultants in collaboration with specialists within the member companies of the IPA. Independent expert peer reviews and opinions were also obtained. The Guide is not intended to be relied upon as a definitive or exhaustive source – readers are encouraged to obtain further information, such as that available in supplier safety data sheets. Furthermore, legal conditions and requirements are constantly evolving and readers are required to verify compliance with applicable local regulations related to worker medical surveillance.

See the Conditions of Use and Disclaimer below.

Chapter 1 – Introduction and Executive Summary

Chapter 2 – Physical and Chemical Properties of PGMs

Chapter 3 – Production and Uses of PGMs

Chapter 4 – Sources of Exposure to PGMs

Chapter 5 – Toxicokinetics of Platinum and other PGMs

Chapter 6 – Toxicity of Platinum and Platinum Compounds (with summaries for other PGMs

Chapter 7 – Medical Surveillance of Workers Exposed to Respiratory Sensitising Platinum Compounds

Chapter 8 – Workplace Monitoring

Chapter 9 – Control Measures and Management Systems

Chapter 10 – Workplace Regulatory Systems and Hazard Communication

CONDITIONS OF USE AND DISCLAIMER: This document should not be relied upon as a substitute for appropriate professional expertise. Furthermore, the information in this document does not constitute legal or mandatory advice. It is for information purposes only. The content of this document is based on the understanding of the circumstances at the time of publication and updates may be required in the future. Any information or recommendation given is non-binding. Whilst reasonable precautions were taken for the verification of the information in the document, it is to be relied upon at the user´s own risk. No representations or warranties of any kind are made with regard to its completeness, reliability, usability or accuracy or possible typographical errors contained and in no event shall the IPA be liable for damages or losses of any kind arising from the use of this document or the reliance on it.

The user is therefore generally obliged to professionally check or to have professionally checked the suitability of the information in the document for its intended use. This document in no way releases a company of its obligations to comply with legally binding rules and regulations. Companies must be aware that antitrust and competition laws may apply for several activities conducted by companies together. The views and opinions expressed in this document do not necessarily state or represent those of the IPA.

Incidence of Platinum salt sensitivity (PSS)

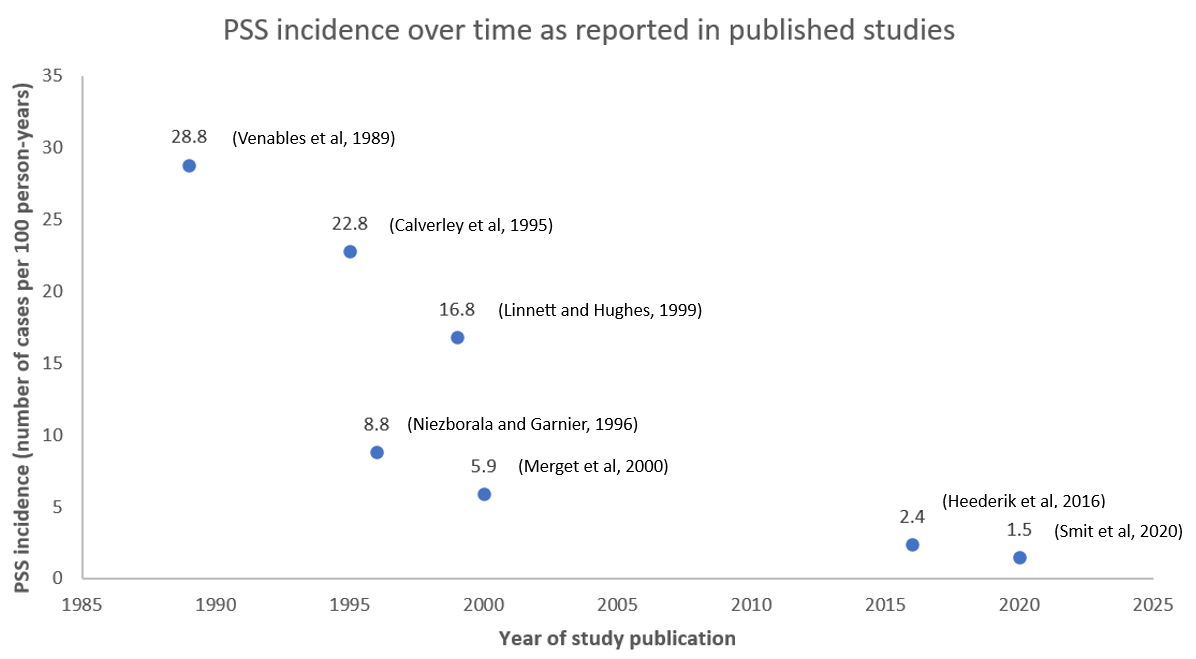

The earliest studies of platinum salt sensitivity (PSS) within PGM refinery workers, published in the 1940s and 1950s, report prevalences of up to and exceeding 50%. Over time, incidence and prevalence of PSS have progressively decreased. The most recent studies of PSS published in 2016 and 2020 report incidence rates of 2.4 and 1.5 cases per 100 person-years, respectively. Data collected by IPA from its member companies show the number of cases of PSS and the incidence rate have continued to decrease since 2010.

The earliest studies of platinum salt sensitivity (PSS) within PGM refinery workers, published in the 1940s and 1950s, report prevalences of up to and exceeding 50%. Over time, incidence and prevalence of PSS have progressively decreased. The most recent studies of PSS published in 2016 and 2020 report incidence rates of 2.4 and 1.5 cases per 100 person-years, respectively. Data collected by IPA from its member companies show the number of cases of PSS and the incidence rate have continued to decrease since 2010.

Industrial hygiene sampling and analysis of soluble platinum

Historically, measurements of levels of soluble platinum in workplaces have used various sampling methods and analytical techniques. To achieve consistent, reliable measurements at the low levels of exposure required, IPA in collaboration with the University of Wisconsin developed a harmonised method for use across the industry.

A review of available equipment and procedures followed by testing of select combinations yielded a standard method for the sampling and analysis of soluble platinum with improved limits of detection.

The method is described in the IPA Guidance Document IPA Harmonised Methodology for the Sampling of Platinum in Workplace Atmospheres.

Further information about the project can be found in the paper published by the University of Wisconsin researchers in the scientific literature:

Shafer MM, Overdier JT, Schauer JJ (2022) An improved method for sampling and analytical measurement of aerosol platinum in ambient air and workplace environments. Science of The Total Environment, 814, 152657

Laboratories used by IPA member companies to analyse soluble platinum by the harmonised method participate in regular analytical testing exercises to confirm proficiency.

Chemical screening test for sensitisation potential

Platinum Salt Sensitivity is associated almost exclusively with complex halogenated platinum substances, of which the chloroplatinates and the pharmaceutical platin chemotherapeutics are by far the most common. In conducting Research & Development activities on platinum compounds, whether a novel platinum compound might have the potential to cause respiratory sensitisation will be an important consideration.

IPA, in collaboration with the University of Wisconsin, demonstrated the Direct Peptide Reactivity Assay (DPRA) was able to correctly identify a selection of platinum substances as either having or not having sensitisation potential. Although the DPRA is only a screening assay and further work may be required to judge its broader performance with metal compounds, this initial research provides optimism for its utility in screening novel platinum compounds.

Further information can be found in the attached Screening tests for chemical sensitisation potential – Direct Peptide Reactivity Assay (DPRA).

PGM mining and silicosis?

Silicosis is a chronic, incurable lung disease caused by inhaling large amounts of crystalline silica dust, usually over many years. Silica occurs naturally in certain types of rock. In South Africa, silica is found in high levels in gold-bearing ore bodies, while it is only present at much lower concentrations in PGM ore bodies.

The South Africa Minerals Council publishes data on silicosis incidence for the various categories of mining in the country. The vast majority of cases are in gold mining, but a smaller number of cases are listed for PGM mining. These are individuals that were working in PGM mining at the time they were diagnosed with silicosis.

IPA’s South African member companies have confirmed that their industrial hygiene monitoring programs show there is only very low exposure to silica within their mines and that when there are cases of silicosis diagnosed amongst their workforce, they are invariably in workers that have previously worked in gold mining. All evidence, therefore, supports the firm belief that there is no risk of silicosis from PGM mining in South Africa.